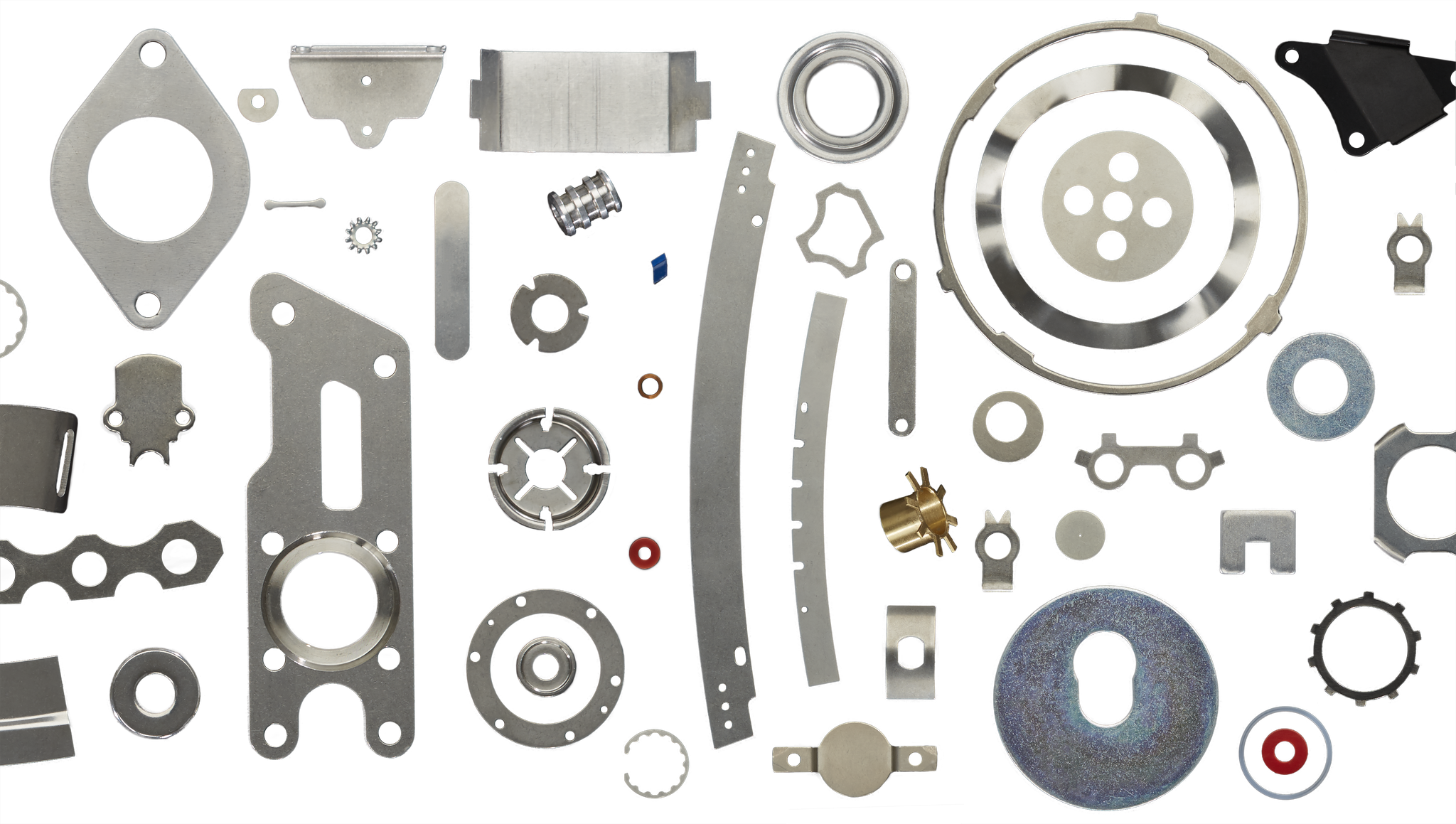

We’re Experts When It Comes to Custom Parts

The Most Reliable Supplier for Specialty

We manufacture millions of parts for thousands of customers worldwide in every industry imaginable. Take a moment to review our service offerings to learn if Phoenix Specialty is the right supplier for your business.

View Video Transcript

Machining

With multiple state-of-the-art CNC Swiss Machines, Phoenix Specialty can produce small precision cylindrical components in low to medium volumes. Swiss Style Screw Machines are well-suited for the manufacturing of small, precision parts and also for long slender parts which could deflect or vibrate if turned on a conventional screw machine or lathe. Swiss Style screw machines provide complete back working on the component, in addition to being extremely efficient and accurate.

Managed Inventory Program

Many customers enjoy the peace of mind that our managed inventory program extends. Simply put, we will produce and store your products in our warehouse so you don’t have to. This means that your parts are always in stock, and ready to ship within the same or next day. We proactively replenish safety stock levels to avoid unplanned production downtime and will automatically replenish goods when needed. Your company will only pay for parts when they are released. Phoenix Specialty understands managed inventory and we’re here to help.

Prototyping Special

Looking to test just a few parts for a new project? It’s easier than ever to get started. With our prototyping special, you can order 25 pieces for a flat fee of $250. No additional tooling charges or hidden fees. When you order within 90 days, the $250 charge will be credited to your next production order. There are certain requirements that must be met in order to take advantage of this offer, so contact our team for more information.

Risk-Free Promise

Phoenix Specialty takes the risk out of sourcing specialty parts. We are the only company offering a written Risk-Free Promise, which guarantees quality, delivery, and price. First, your parts will be manufactured to your unique specifications. Secondly, your items will ship on-time. Finally, you will receive a 12-month price lock, ensuring prices will stay the same for one full year after your order.

Secondary Operations

When in-die production is neither feasible nor cost-effective, we offer secondary value added operations for the parts we manufacture. These services include: tapping, double disk grinding, O.D. chamfer and radius, painting and forming, counterboring and reaming, electro etching and ink stamping, impression stamping and dot peen, countersinking, bag and tag, dowel and tube packaging, and even labeling.

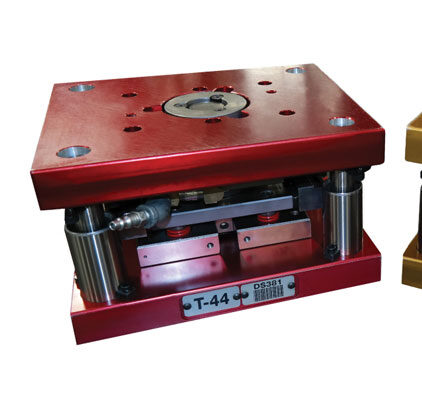

Stampings

Phoenix Specialty has the capability to meet your exact stamping needs, thanks to our in-house, fully-equipped, modern machine shop that produces a wide range of tooling. With a warehouse containing over 1.5 million pounds of 300 different materials in thousands of thicknesses and widths, including exotic ones, we can manufacture any stampings to your precise specifications. Talk to our team about the exact specifications of your part to discuss the possibilities of utilizing precision and custom stampings.

Water Jet

When conventional stamping methods may not be applicable, water jet cutting may be an alternative. This capability can provide the same quality parts in smaller volumes, eliminating the need for production tooling. Water jet allows us to cut material without interfering with its inherent structure and properties, minimizing the effects of heat. Depending on the type of project you are working on, water jet cutting is an excellent option to consider.

Frequently Asked Questions

Do you design or engineer parts?

No, although we work with our customers and provide samples whenever possible.

Do you have a minimum quantity or order amount?

No, we do not have a minimum order.

Do you have a catalog or standard size listing that can be viewed?

No. Our parts are custom. We manufacture to our customer’s blueprints or samples.

Do you manufacture Lock Washers?

We do not manufacture hardware store type lock washers. However, there are many other types of washers that are considered locking. Send us your print, and we will determine if it falls within our product market. (You can go to our Order page to see the styles of formed washers we do work with.)

Do you sell shim stock or material?

Sorry, but we are not a supplier of raw material. We supply specialty components.

Do you sell to individuals?

No. Our customers are manufacturers in a variety of industries.

Is there a tooling charge?

No. There are no separate tooling charges for our compound tooling.

What are Belleville Washers?

Belleville Washers are typically used as springs, or to apply a pre-load of flexible quality to a bolted joint or bearing. Belleville Washer or Belleville spring – a disc shaped spring commonly used to apply tension to a bolt (and also in the initiation mechanism of pressure-activated landmines). Some properties of Belleville Washers include: high fatigue life, better space utilization, low creep tendency, high load capacity with a small spring deflection.and possibility for high hysteresis (damping) by stacking several belleville washers on top of each other in the same direction. Most often, you’ll find Belleville Washers in applications where you have to connect bare, soft aluminum to aluminum or copper, or where you have conditions of high current loading or cycling. These washers do wonders for accommodating thermal cycling, but they can’t eliminate all the problems resulting from poor workmanship. You must prepare the joint properly (as with any connection), but the key is selecting the proper design and size of Belleville Washer for the fasteners and conditions of your application. Phoenix Specialty Mfg Co manufactures Belleville Washers for the following industry segments: Aerospace Agriculture Automotive Building Products Compressors Consumer Goods Belleville Washers Use If need more information on the use Belleville washers please contact Phoenix Specialty at 844.772.7048 Phoenix Specialty Mfg Co. Bamberg, SC has been making Belleville Washers or Belleville Springs for over 100 years. When considering a supplier of Belleville Washers, Phoenix Specialty is your single source for Belleville Washers. If we do not have it in stock from our inventory of over 4 million parts Phoenix Specialty can custom make Belleville Washers to your specification and ship them within 2 weeks of a custom order.

What are standard tolerances?

We specialize in precision, specialty components manufactured to your requirements and specifications. That includes tolerances. Tell us which tolerances meet your engineering needs, and we’ll manufacture the parts to those tolerances.

What are your standard lead times?

At Phoenix, we have the shortest lead time in the industry. For a custom flat round part, with no outside services, we typically ship within 2 weeks or sooner if material is in stock. Phoenix Managed Inventory items are available for shipment within 24 hours.

Where are you located?

We are located in Bamberg, SC.